Veneer then assemble a field, or assemble THEN veneer a field?

From Joe on Discord

I’ve a bunch of MDF sitting round and a few veneer I bought at a storage sale, so I used to be pondering of constructing a veneered field. What’s the typical approach to go about it? Assemble the field, then veneer it? Lower the items, veneer them, then assemble? Veneer the MDF face, reduce the items, then veneer the perimeters?

I can see any of these methods working, however I’m unsure which method often works out the most effective.

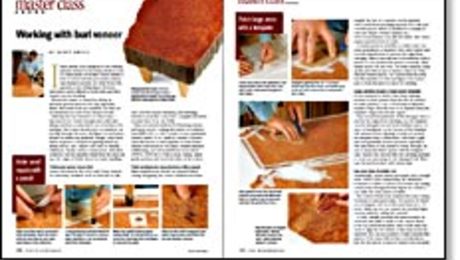

5 questions on veneering with burl

From TJ on the FWW discussion board

That is my first try at walnut burl veneer, so I’ve a number of questions relating to making a balanced panel for my venture.

I’m planning on a small case piece utilizing 1/2″ Baltic birch ply as my substrate. Since I’m unfamiliar with burl I don’t know what to steadiness it out with on the inside. My questions are;

1. When utilizing a burl, must you use a crossbanding below it? Will such a layer improve stability by the elevated glue floor?

2. Since I can’t discern a grain sample in a burl, is there any have to be involved about directionality?

3. Do I have to be involved in regards to the inside veneer’s species or directional placement to make sure steadiness and a secure panel? Are there higher woods to make use of than others? Is the T&R ratio an element?

4. Would an MDF-faced ply core be higher than the birch?

5. Lastly, would a inflexible glue be higher to make sure stability?

Each two weeks, a group of Tremendous Woodworking staffers solutions questions from readers on Store Discuss Reside, Tremendous Woodworking‘s biweekly podcast. Ship your woodworking inquiries to [email protected] for consideration within the common broadcast! Our continued existence depends upon listener help. So in the event you benefit from the present, remember to depart us a five-star ranking and possibly even a pleasant touch upon our iTunes web page. Be part of us on our Discord server right here.

For the sake of appeasing the robots, right here is the present transcript, cleaned up utilizing AI:

Welcome to Store Discuss Reside, episode 360. Earlier than we get began, we’ve bought a few bulletins in regards to the format and personnel of the present.

First, I need to let everybody know that Amanda is now not with Tremendous Woodworking. We want her the most effective, and may’t wait to see what she has in retailer sooner or later.

With Amanda now not with us, we felt the necessity to usher in a second co-host, and we’ve elevated Vic from frequent co-host standing to a real 50% host—somebody who’s going to assist drive the way forward for the podcast.

Ben: Hey, Vic.

Vic: Hey, man. How’s it going?

Ben: That’s a technique of doing it, huh?

Vic: You betcha.

Ben: When every little thing went down, I assumed, “It’s time for Vic to drag a heavier load round right here—take half the episodes—and see what occurs.” We’ve been having enjoyable as a duo for some time, so thanks for being a much bigger a part of the present. You’ve already been an enormous half, however now you’re an plain pressure.

Vic: I recognize it—simply being provided the chance. I feel it’s nice.

Ben: We determined we’re going to commerce off internet hosting. You’ll host an episode, then I’ll host an episode.

Vic: Yeah.

Ben: I’m a bit of involved that it means we’d not find yourself on the present collectively, so we want to verify we do every now and then—as a result of a few of the finest Store Discuss Lives are whenever you and I are on it collectively.

Vic: We are able to’t sustain that velocity the entire time. It’s not honest to the remainder of woodworking and the podcast business. We’re up right here and all people else is simply making an attempt to maintain up.

Ben: The Olympics are going proper now, and there’s an Italian downhill skier—I don’t keep in mind her identify—however that’s you and me, Vic.

Vic: Maintain on. Let’s get this proper. You and I are the Italian lady skier within the Olympics?

Ben: Sure.

Vic: It takes two of us to equal a kind of.

Ben: She simply received two gold medals, so I don’t know why you assume one in all us could be able to doing something. However sure—we’ll ensure we stay a duo every now and then.

Ben: I’m excited as a result of you have got an entire completely different community of woodworkers than I do, and an entire completely different perspective on who you need to amplify. You’ve all the time been an enormous a part of the present, and I’m grateful you’re taking a good greater position.

Vic: It’s going to be good.

Ben: Beginning with this episode, we’ve bought Steve Der-Garabedian on, who has been a good friend of Vic’s for a few years, an unbelievable woodworker, and he focuses on veneer work. I like Steve as a result of he makes issues approachable. Veneering freaks lots of people out as a result of they assume it’s too exhausting or too “subsequent stage,” but it surely’s not. It’s approachable. Having Steve on goes to be nice, and it opens up an entire new realm of woodworking potentialities—a world the place you don’t have to fret about grain path.

Veneering is sort of a ability comparable to dovetailing, however dovetailing doesn’t open up an entire completely different design universe. Veneering does. When you be taught it and recover from that hump, every little thing adjustments for you as a woodworker.

We discuss rather a lot on this episode about Steve’s guide, Veneering Necessities: Easy Strategies and Sensible Tasks for At present’s Woodworker. We’ll hyperlink to it within the present notes. Vic, why don’t you’re taking us away on your first episode?

Vic introduces Steve

Vic: Sounds good. That is thrilling—two-thirds Canadian, one-third American manufacturing right here. I really feel like I ought to get further credit score as a result of I like Canada.

Ben: And we love you.

Vic: Canada’s most likely my favourite nation.

Ben: Despite the fact that you want snow tires?

Vic: I take into consideration that far too usually: “The place would I retailer snow tires?”

Ben: You possibly can use them the place you’re, Ben. You guys get a good quantity of snow.

Ben: We simply don’t go anyplace. I had a cousin come up from California—late spring—however we had a whiteout for ten minutes. She panicked. I mentioned, “Calm down, I’ve bought snow tires.” She mentioned, “You’re making that up. There’s no such factor as snow tires.”

Vic: That’s like after we used to invent issues like snow snakes for folks doing winter coaching.

Ben: Snow tires aren’t actual.

Vic: Steve, you’re identified up right here in Canada—and everywhere in the world—on your veneering prowess. You actually have a guide, which is improbable.

Steve: I do have a guide right here someplace.

Vic: You don’t have to point out it—most individuals take heed to the podcast. I used to carry issues as much as the digicam, and Ben informed me that’s no good. So it’s not present and inform—it’s simply inform.

So earlier than we get into questions: why is veneer so necessary to you?

Why Steve bought into veneer

Steve: I get requested that rather a lot. I went to Rosewood Studio such as you did. I researched every little thing earlier than I went there, and after I noticed veneering, I assumed, “I’ll take a break throughout that.” Stable wooden or nothing.

Then I bought there and was proven the way to do it correctly. I spotted it’s not simply low cost stuff that delaminates six months later. When it’s performed proper, it’s wonderful.

One large factor is you eradicate wooden motion. One other is: if you wish to work with the most effective woods on the planet, you should be taught to veneer. I additionally assume we have to be environmentally aware, and veneering helps with that. I keep in mind listening to Mike discuss in regards to the emerald ash borer—how white ash won’t be round for much longer—and my thought was: get it and switch it into veneer. You lengthen the useful resource.

My favourite method is utilizing a vacuum bag. It jogs my memory of that Popeil hen roaster: set it and neglect it. Similar factor with the vacuum press—throw it in there and neglect it till eight hours later.

Vacuum pump discuss

Ben: Vic, I’m already going to throw you for a loop. You’ve bought a legit vacuum pump—what’s the model?

Vic: It’s VacuPress—the orange smaller one.

Ben: Steve, do you have got a VacuPress?

Steve: I do. The VacuPress 300, which I imagine is inexperienced.

Vic: Query for the viewers: do I really want that? Can I not get away with a Harbor Freight vacuum pump for some time?

Steve: I haven’t seen the Harbor Freight one. Princess Auto—no matter you name it. What it comes right down to is quantity. A top-of-the-line VacuPress might most likely run a number of 4×8 baggage without delay. Mine will comfortably do a 4×8 bag, no points, and you may vacuum clamp as effectively.

Smaller pumps—relying on the dimensions of the venture and bag—won’t evacuate air rapidly sufficient earlier than the glue units.

Ben: You additionally run into overheating, proper?

Steve: Once I was writing my guide, I requested the man who began VacuPress if it was okay to maintain the pump operating lengthy. He mentioned sure—hold it operating so long as you need. When you’re going longer than half a day or a day, take the duvet off so it cools higher.

Ben: Take its blanket off. I used to have a automotive like that—pop the hood whenever you run into 7-Eleven.

Ben: Right here was my pondering: glue dries in half an hour. Does it have to be within the bag that lengthy?

Steve: Sure. I like Titebond Chilly Press for Veneer. The bottle says minimal 45 minutes as much as two hours, however I don’t take something out of the bag in lower than six or seven hours. If it’s bent work, it’s in a single day.

The one time I take it out earlier is that if it’s an enormous venture and I can’t veneer each side on the identical time. I’ll veneer one aspect, bag it about 45 minutes, pull it out, veneer the opposite aspect, then bag it seven or eight hours.

When you do your urgent on the finish of the day—ensure every little thing’s sealed and never dropping air—then return to the home and let it run in a single day.

Ben: One factor that made me completely satisfied: Roarockit has a package that for about $100 does the identical factor as a way more costly press. Your fingers and a one-way pump are the vacuum pump. You’ll be able to even use a store vac to evacuate many of the air first.

Steve: I let my college students do it.

Ben: That’s how he sells electrical ones.

Steve: I do have an adapter for my electrical pump that lets me do the handbook pump. I don’t present them that till the tip of the day.

Ben: I even tried a kind of large Ziploc vacuum storage baggage on a flat press. I wouldn’t belief it for bent work, but it surely labored completely for flat. I used to be getting about 12 inches of mercury. I like larger than that, but it surely was sufficient to get the job performed. These baggage are low cost.

When you’re entering into it, Roarockit is accessible. However I hold pondering: for CNC workholding and different causes, having a vacuum pump within the store could be good. Then you definitely see HVAC vacuum pumps for $120 and assume, “What’s the distinction?”

Steve: Your pump isn’t operating the entire time throughout a six-hour session. When you get seal, it comes on possibly as soon as each 20 minutes for about 10 seconds.

Ben: That’s extra usually than I anticipated. With Roarockit, are you maintaining a tally of it and hand pumping, or letting it roll?

Steve: It relies on the seal. If the butyl tape wants changing, I’m maintaining a tally of it. However I’ve left the home and are available again to discover a leak and the bag down round 12 or 11 inches of mercury, possibly decrease. Not splendid, but it surely nonetheless labored. It doesn’t must be excellent.

Ben: No, every little thing must be excellent earlier than you begin. You want all of the gear, all of the ability, all the cash. And in the event you make a mistake, simply promote all of it.

Steve: If it doesn’t work out, take pennies on the greenback and eliminate it.

Query from Joe (Discord): veneer an MDF field?

Vic: We’ve bought a query from Joe on Discord: “I’ve a bunch of MDF and veneer from a storage sale, and I used to be pondering of constructing a veneered field. What’s the standard method? Assemble the field then veneer it? Lower the items, veneer them, then assemble? Veneer the MDF face, reduce the items, then veneer the perimeters? I can see all of those working—what works finest?”

Steve: You possibly can do all of that. However in the event you assemble the MDF right into a field first, it’ll be a lot tougher to press the veneers. My intuition is to veneer whereas it’s nonetheless flat—in items, or one large piece—then reduce it and do the joinery to make the field. Some other method makes it exhausting to press the veneer to the MDF. And you should do each side.

With MDF, it’s not as unhealthy in the event you veneer one aspect and wait a day to do the opposite. However Baltic birch stunned me: I veneered one aspect and waited half a day or a day for the opposite, and it had already warped.

So veneer it earlier than assembling the field.

Ben: Once you had been writing your guide, did you do experiments—simply veneer issues and see what occurs?

Steve: I did. I felt accountable to the reader. I examined completely different supplies and thicknesses: hardboard, MDF as much as three-quarter, completely different thicknesses of Baltic birch, and wiggle wooden. I assumed Baltic birch could be the strongest and never warp, but it surely warped the worst—potato-chipped. MDF was higher however finally did as effectively.

One other experiment: we’re all the time informed you should use veneer tape as a result of masking tape will depart a hump. I examined it.

Ben: Clarify: a hump in what?

Steve: Once you joint and be a part of veneer, you would possibly use masking tape on the glue aspect to carry it collectively, flip it, put veneer tape on the highest, then peel off the masking tape earlier than gluing. We’re informed masking tape is simply too thick to depart there. I discovered masking tape does depart a hump if left on the glue aspect—and it additionally creates a glue-resist space. One layer can present it; two layers undoubtedly do.

As for veneer tape, as much as three layers could be okay, but it surely relies on veneer thickness and species. Three layers can depart a bump. You’ll be able to sand it out, however you solely have a lot veneer.

Ben: The important thing to not sanding by means of veneer is to not sand by means of veneer.

Vic: Like Yoda.

Veneer tape fundamentals and course of

Ben: Veneer tape is that skinny tape—like gum tape—completely different widths, and variations with holes: two-hole, three-hole, five-hole, nine-hole.

Steve: Machine stitchers use the huge stuff. A machine stitcher is a big machine—feed in two items of veneer and some seconds later it comes out stitched completely.

There’s additionally threaded variations and different adhesive techniques.

Ben: Stroll by means of your course of.

Steve: I joint and be a part of two items of veneer. On the glue aspect, I exploit masking tape throughout the grain to carry it collectively—possibly each three or 4 inches. Then I flip it, moist veneer tape, and do the identical throughout the joint, then one lengthy strip alongside the joint.

As a result of veneer tape will get moist and I exploit an excessive amount of water, I sandwich the veneer between two items of MDF so it doesn’t curl. By the point I prep the bag and glue, I peel off the masking tape from the glue aspect. The veneer tape is holding it collectively. Then I glue the substrate and press.

Ben: So veneer tape isn’t between the substrate and the veneer?

Steve: Normally it’s on the highest. However you should utilize veneer tape on the glue aspect in sure conditions—like cross-laminating a backer veneer when your face veneer grain path wants to vary. In that case I exploit the veneer tape with holes so there’s glue-to-wood contact by means of the holes.

The holes can even allow you to examine the seam.

It’s simple to stretch masking tape an excessive amount of on the preliminary joint and trigger one veneer to slide below the opposite, which creates a double layer in spots—exhausting to repair. Having the ability to see the seam offers assurance you haven’t performed that.

Ben: Do you purchase holey veneer tape or stable?

Steve: Each. Holey tape is harder to take away. Stable peels off simpler. Holey isn’t unhealthy—scrape and sand and it’s gone.

Vic: So for Joe: veneer inside and outside first, reduce it up, then assemble the field.

Ben: Issues for joinery on veneered items?

Steve: Deal with it in another way. When you’re reducing rabbets just like the Ferrazzi technique, sharp instruments matter. A helical router bit works higher. On the desk noticed, a blade meant for melamine/MDF/veneer works effectively—extra tooth, damaging rake (just like aluminum-cutting blades). It reduces tearout.

A observe noticed works nice due to the splinter guard and the blade motion, particularly with a blade made for veneer. Lay the observe on the veneered floor.

Ben: Steve even cuts and joints veneer with a observe noticed and a jig. A observe noticed could be the final word veneer jointing machine.

Steve: Even nasty curly ash veneer—observe noticed does an unbelievable job.

Sponsor learn (saved as-is, minus time code)

You like wooden. You lovingly select the wooden you employ for tasks. Then you definitely spend numerous hours measuring, reducing, gluing, becoming a member of, till your work meets your imaginative and prescient. At Sutherland Wells, they honor your craftsmanship with conventional oil finishes that match the look, really feel, and safety that your work deserves. Their small-batch, handcrafted finishes and stains begin with the very best high quality, cold-pressed, American-grown tung oil, polymerized of their Windfall, Rhode Island location, for unmatched high quality and consistency. Their low-VOC and VOC-exempt versatile finishes improve grain, penetrate deeply, resist yellowing, and improve the pure great thing about wooden whereas offering lasting safety. Sutherland Wells loves wooden, too. Take 10% off your first order with code FWW26 and see simply how lovely wooden could be.

Discussion board query from TJ: Walnut burl veneer + balanced panels (5 components)

Vic: One other query from the discussion board, from TJ. 5 components—we’ll rapid-fire.

TJ’s Q1: “When utilizing a burl, must you use a crossbanding below it? Will it improve stability by rising glue floor?”

Steve: I don’t assume you want to. It’s further work you don’t want except there are potholes within the veneer. Burl usually has pinholes and glue can bleed by means of—but it surely’ll bleed by means of whether or not you crossband or not in the event you apply extra glue. Use veneer glue and blend the solids again in. If it bleeds by means of, sand it and it’s gone.

Ben: So veneer glue isn’t nearly open time—you’re saying there are added solids in Titebond Chilly Press?

Steve: Sure. VacuPress has Unibond One, comparable: PVA with solids, just like Titebond Chilly Press. Open time/set time is just like Titebond III.

I used to make use of Unibond 800 (formaldehyde-based) for longer open time and no chilly creep, however I finished utilizing it. It dried rock stable; squeeze-out was like shards of glass.

TJ’s Q2: “Since I can’t discern grain sample in burl, do I have to be involved about directionality?”

Steve: Probably not, aside from aesthetics. Some burl sheets have straight grain popping out of it. Burl sizes are restricted, so on large work you is likely to be jointing a number of items and it might look busy. Grain path is much less of a priority. When you’re nervous, veneer over one thing man-made like hardboard or MDF.

Ben: Burl can get garish rapidly.

Steve: Much less is extra.

TJ’s Q3: “Do I have to be involved about inside veneer species or directional placement to make sure steadiness and stability? Higher woods than others?”

Steve: No. If it is going to be seen, decide one thing lovely. It doesn’t have to be burl on the opposite aspect. The rule is: what you do to 1 aspect, you should do to the opposite aspect.

Ben: Does it must be equal thickness veneer on each side?

Steve: In an ideal world, identical thickness, however realistically it’s not. It’s actually the glue sealing each side that issues. Thickness doesn’t actually come into play most often.

TJ’s This autumn: “Would an MDF-faced ply core be higher than birch?”

Steve: I don’t assume it issues. Veneering is placing lovely wooden over ugly wooden. With fashionable glues, bonding isn’t the problem. In my store I hold it easy: MDF and Baltic birch. You’ll be able to veneer over metal or glass.

Ben: When you might solely have one substrate?

Steve: Quarter-inch MDF.

Ben: Why quarter-inch?

Steve: As a result of I can stack it and make it thicker if I must.

Ben: I all the time heard MDF explodes with water-based glue.

Steve: Don’t put MDF in a cup of water. However I spotted: Michael Fortune veneers over MDF, so it’s effective. No grain path worries. Quarter-inch MDF is the final word substrate.

Ben: What about particle core? Cabinetmakers swear it’s flatter than MDF.

Steve: Baltic birch high quality has been disappointing the final a number of years—usually warped. MDF is good and flat. I haven’t gone out of my method to make use of particle core; I’ve solely used it after I wanted one thing heavier. For acoustic causes I’ve made sound boards with particle core.

Ben: Speaker cupboard materials?

Steve: Most likely. A number of audio system use MDF.

TJ’s Q5: “Would a inflexible glue be higher to make sure stability?”

Steve: No. Fashionable glues do an incredible job. Simply ensure you stir the solids again into the adhesive. You’ll be able to’t shake it—you should stir it.

Ben: Too many Bonds. For Titebond, you should stir.

Steve: Titebond informed me: don’t shake it. Stir the solids again in. I didn’t need to spend my time stirring glue, so I purchased low cost fly swatters, reduce one down, bent it, chucked it in a drill, and now I stir glue with the drill as a substitute of blending it like a potion.

Vic: It is best to promote that to Titebond.

Wrap-up and present notes

Ben: I’m actually completely satisfied we had Steve on. Folks nonetheless really feel tentative about veneering. What I like about Steve is he makes the entire course of approachable. In his guide he veneers to steel so you can also make a veneered magnetic board. It appears to be like unbelievable, and it’s not troublesome.

Any time you be taught one thing new in woodworking, it’s exhausting till you already know. Then it’s like dovetails: folks freak out, however they’re simple to chop. Arduous to excellent, however practical dovetails come rapidly.

Steve’s guide doesn’t get too valuable—it’s “right here’s the way you do it,” after which you may take off. Thanks for being right here, Steve.

Steve: Thanks. I recognize the sort phrases. Veneering could be performed cheaply. The primary venture within the guide could be performed for lower than $30. Even in the event you don’t purchase a vacuum bag, you probably have a garments iron that reaches the cotton setting and a few PVA glue, you may veneer with an iron and glue you have already got. If you would like home concord, purchase one other iron for $20 and hold your personal. Veneering is superior. It’s not that tough.

Ben: What’s the identify of your guide?

Steve: Veneering Necessities, by Cedar Lane Press.

Ben: How do you spell your final identify?

Steve: Der-Garabedian. D-E-R hyphen G-A-R-A-B-E-D-I-A-N.

Ben: Thanks for being with us, Steve.

Steve: It was superior. Thanks.

Ben: Earlier than we go, right here’s what you’ll discover on this week’s present notes: Adrian Farzadi’s Veneered Packing containers With a Twist (article and video workshop), Owen’s Plywood and Sheet Items for the Woodworker, Scott Grove’s Working with Burl Veneer, and Bob Van Dyke’s Introduction to Wooden Veneering (together with flattening figured and burl veneers). I’ll additionally embody a VacuPress video overlaying their merchandise and various kinds of vacuum pumps, together with why you don’t need to use a finances pump from a neighborhood device retailer.

When you’re watching on YouTube, please click on the thumbs up. When you’re listening on Apple Podcasts, a five-star evaluate could be superior. Thanks once more to Vic for stepping up. Thanks to Jeff Rose for expertly mixing and assembling every little thing we’re doing right here. We’ll see you in two weeks with one other episode.

Join eletters right this moment and get the most recent strategies and how-to from Tremendous Woodworking, plus particular affords.