A number of the most vital instruments in my store are my chisels. Whether or not it’s chopping, carving or paring, they’re in my palms all day. As I’ve gotten older and my arthritis/tendonitis has gotten worse, my wants have modified. On this weblog, I’ll discuss my most well-liked chisel deal with and make a alternative deal with to go well with my wants.

I used to have socket chisels within the Stanley sample, made by Lee Valley/Veritas. They have been very good, however the fancy fashionable metal was arduous to sharpen and the small handles by no means felt proper. The swell within the deal with close to the socket is meant to cease your hand from sliding up and provide you with a registration space. I believed these have been high-quality till I held an outdated Ward chisel that belongs to my pal and fellow luthier Ben Bonham. Once I say “Ward,” I don’t imply the American “Montgomery Ward,” however as a substitute the Sheffield agency of “Ward and Payne”. Ben’s chisel had a giant, symmetrical deal with that simply felt proper to me.

I did some analysis and observed discovered chisels made by a number of makers, all from the Sheffield area of England, which are related. I actually like these chisels for 3 causes: 1) The large deal with with a swell within the center is extra comfy for my drained palms to seize. 2) The dearth of a entrance swell makes it simpler to choke up on the deal with and grasp close to the blade, vital for my close-up luthier kind work. 3) The outdated metal is usually good, and far quicker to sharpen than the Veritas tremendous metal.

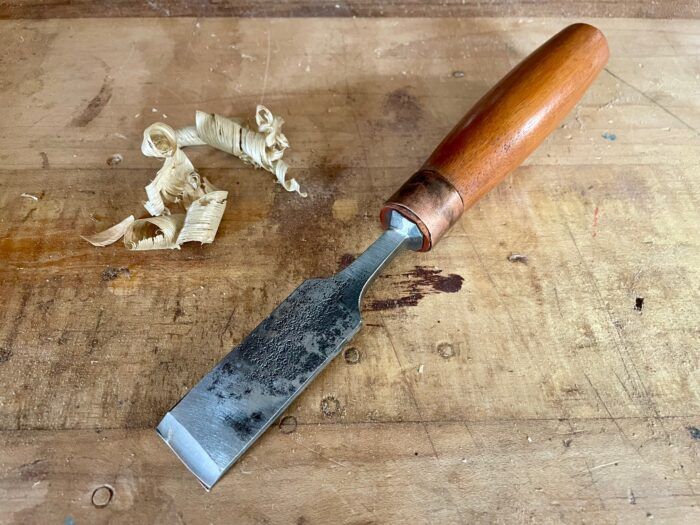

These UK chisels have a spur or tang coming off the blade that sinks into the deal with. A metallic ring known as a ferrule surrounds the tang to cease the deal with from splitting. It is a distinction to the socket chisels which are extra widespread within the US.

Over time, I’ve gravitated in direction of the handles which are slightly outsized on these tang chisels. For at the moment’s undertaking, I’ll make a deal with for every model of chisel, however about 10% larger than the norm. We’ll give attention to the tang model at the moment and the socket model subsequent time.

Step one is to seize a scrap of Mahogany and aircraft the corners off earlier than I roughly flip it spherical on the lathe. Subsequent, I mark with a pencil the vital locations of transition for every chisel model. I switch the wanted dimensions from the pattern handles with a caliper, including a bit to the scale.

Crucial components of the handles are the areas that may work together with the metallic components: the tapered finish for the socket deal with and the ferrule for the tang chisel. These take just a few rounds of measuring and flippantly turning with the skew chisel until they’re proper. A bit of sanding and they’re able to half off the lathe.

For the ferrule, I take advantage of a bit of copper pipe from the ironmongery store. It should look totally different than the extra conventional brass, however is cheaper and simpler to get.

The toughest a part of the tang deal with is boring the tapered, diamond formed gap for the tang. I take advantage of three totally different drill bits, every marked with a bit of tape for depth, to begin the tapered gap. Then I take advantage of a collection of information and chisels to form the outlet, steadily testing the match. The ultimate match ought to require just a few faucets on the butt to seat the tang, no glue required. I’ll add a leather-based washer as properly.

Subsequent up is sanding, shellac and black wax. This chisel was a rescue, with lots of pitting and a reasonably brief size. I floor, filed, sanded, polished and sharpened it, which is lots of arduous work that isn’t good for my drained palms, bit I take pleasure in saving a software like this from the landfill. It might not look a lot, however I received it a lot sharp on my oil stones and I do know it is going to be helpful.

I’ve a big store for a one-person operation, so I typically place a software like this at a piece station away from foremost bench. It saves me from strolling far and wide to search out what I would like. If I labored out of a chest or in a smaller store, these further instruments could be a burden. However for now they save me time and are a pleasure to rescue.

Keep tuned for half 2, the place I’ll deal with the socket chisel deal with.

Join eletters at the moment and get the most recent strategies and how-to from High quality Woodworking, plus particular affords.