Synopsis: CBN wheels for bench grinders have turn into fashionable amongst wooden turners, whose instruments are usually made with high-speed alloys which can be powerful on conventional wheels. Chris Gochnour needed to know if CBN wheels may very well be used to sharpen chisels and aircraft blades, that are sometimes made out of softer steels. He was involved that these softer steels would persist with the CBN wheels, presumably ruining them. In checks utilizing each a conventional grinder and a Tormek grinder, Gochnour discovered CBN wheels to have all the advantages of conventional wheels, with not one of the downsides.

I’ve a wood-turning pal who teaches an occasional class at my Salt Lake Metropolis workshop. He brings plenty of bench grinders with him every time, that are geared up with CBN wheels. These work superbly on turning instruments, which are usually made with high-speed alloys which can be powerful on conventional wheels.

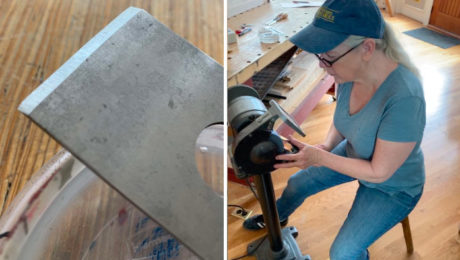

CBN stands for “cubic boron nitride,” an industrial abrasive that’s second solely to diamond in hardness. The CBN particles are electroplated onto a metal or aluminum wheel, and so they have an virtually limitless lifespan for woodshop use. Not like conventional molded grinding wheels, CBN wheels run completely true and by no means should be dressed, a course of that reduces the dimensions and longevity of a conventional wheel. Meaning you gained’t have to regulate your device rests to accommodate a wheel that will get smaller over time. It additionally means you don’t should fuss with wheel dressers.

I had additionally heard that CBN wheels reduce sooner than conventional wheels. Maybe most significantly, they have been additionally reported to run cooler than their old-school counterparts, which may overheat device edges, eradicating their hardness and mood and forcing you to grind previous the broken space to get again to hardened metal.

Being primarily a furnishings maker reasonably than a wooden turner, I used to be to learn how these new wheels would fare with chisels and aircraft blades, which have a tendency to make use of barely softer steels than turning instruments. These supplies embody 01 steels, the kind utilized in conventional woodworking instruments; harder A2 steels; and PMV-11, a proprietary powdered metal used completely in Veritas instruments, bought by Lee Valley.

My fear, nonetheless, which was shared by my wood-turning pal and others, was that these barely softer steels would persist with the CBN wheels, clogging (or “loading”) their abrasives. If there have been no option to costume them and expose recent abrasive grains, as with conventional wheels, the CBN wheels would turn into much less efficient, and presumably even be ruined.

Now, primarily based by myself testing and that of others, I can verify that this fear is unfounded, which leaves woodworkers free to get pleasure from all the advantages of those thrilling new wheels.

The underside line is that this: After 35 years as an expert woodworker, I’ll be altering my grinding wheels to CBN.

Sorting by way of the various choices

To assist me higher perceive CBN know-how and its capabilities, I collaborated with Ken Rizza, the founding father of Wooden Turners Wonders (WTW), one of many main retailers of high-quality CBN wheels. Rizza has plenty of useful movies on the corporate’s web site (woodturnerswonders.com), which satisfied me that these wheels would possibly work simply as properly on conventional device steels as they do on extra unique alloys.

CBN wheels are bought in a wide range of shapes, sizes, and grits, so my first step was deciding which of them to strive. Rizza helped me determine finest bets.

CBN wheels are pricier than conventional grinding wheels. For instance, my favourite for the standard bench grinder prices about $160, in comparison with $50 or $60 for a high-quality conventional wheel.

My objective was to decide on the one wheel that will work finest on a standard bench grinder, whether or not slow-speed (roughly 1,725 rpm) or customary (3,450 rpm, kind of). I did that, after which did the identical for my Tormek grinder.

Testing reveals massive advantages

Woodworkers aren’t at all times conscious of this, however conventional molded wheels are sometimes out of true aspect to aspect and turn into considerably oval in form with repeated dressing, which makes them out of true entrance to again as properly. This creates vibration in each instructions, making grinding rougher and fewer environment friendly.

A CBN wheel is machined, then again, and subsequently runs true (as true as your grinder does anyway). In consequence, the face of a CBN wheel appears like a strong floor in use, and the device feels very regular in your hand. That additionally makes grinding extra environment friendly. That is partly why the CBN wheels beat my conventional wheel on uncooked grinding velocity, regardless of their massive variations in grit sizes.

After the velocity check, I used to be leaning towards the 180-grit CBN wheel, so I took the sides that I floor on that wheel to my waterstones for ultimate honing and located that I may skip the primary stone I normally use and bounce proper to my 1,000-grit stone, with no loss in honing effectivity. It is a massive profit for hand-tool customers. As for burning, it took simply eight seconds of steady grinding on my conventional wheel to start to darken the metal on the tip of the device. On the 180-grit CBN wheel, I floor repeatedly for a minute, with no signal of darkening and burning. The device turned too scorching to carry at that time, however there was nonetheless no burning current.

This just about eliminates the principle hazard related to conventional grinding wheels. You gained’t should grind with such a feather-light contact on CBN wheels, and you may most likely eliminate your little cup of water too, the one you dunk the tip of the device in each 5 or 10 seconds to maintain it from burning.

Through the few months I’ve been utilizing the CBN wheels, I can’t say that I’ve observed any important loading of metallic between the abrasive grits. I did load up the wheel with Slick-Stick, nonetheless, once I utilized it too liberally. But it surely’s simple to wash off.

Just a few extra suggestions

Closing ideas

Used accurately, a bench grinder gives the quickest option to create a recent bevel. In case you’ve had dangerous experiences with bench grinders up to now, a CBN wheel offers you all of their advantages with out the downsides. And in contrast to conventional grinding wheels, CBN wheels don’t have to be dressed, saving you much more time.

—Chris Gochnour is a contributing editor to FWW.

Nice Woodworking Really helpful Merchandise

Wen Diamond Grinding Wheel

Diamond grinding wheel is ideal for flattening grinding wheels earlier than honing chisels and aircraft blades

Norton Water Stones

This equipment consists of all the pieces you want to sharpen your whole blades, with water stones in 4 grits and a separate stone to maintain them flat.

Join eletters at the moment and get the most recent methods and how-to from Nice Woodworking, plus particular gives.

Obtain FREE PDF

while you enter your e-mail tackle under.