Initially printed in High quality Woodworking #20

For storage or cargo it’s typically advantageous for a tabletop to be rapidly detachable, whereas in day by day service the highest needs to be mounted securely sufficient for one individual to have the ability to shift the desk inside a room. Right here’s a pair of building strategies that require no {hardware}—one for tables with apron frames, a variation for pedestal frames.

Apron body

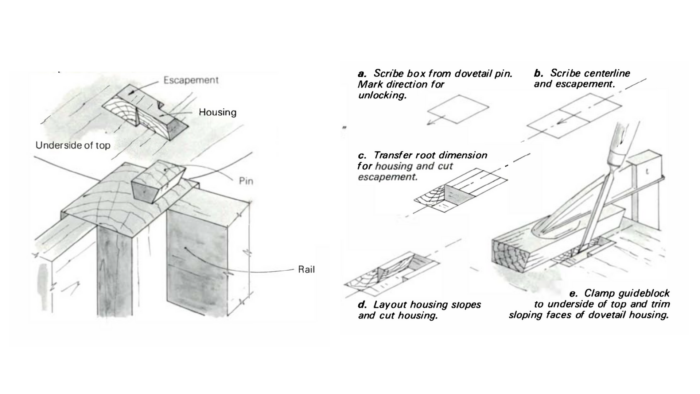

This methodology makes use of dovetail pins minimize on the tops of the legs and dovetail housings with escapements chopped throughout the grain of the underside of the highest. To assemble, drop the highest over the pins and push it throughout the body to lock the pins of their housings. To disassemble, push the highest from the alternative aspect till the pins register of their escapements, and carry the highest away. Correctly dimensioned, the system is invisible when locked up.

When sawing the legs, depart additional size on the high finish equal to about half the thickness of the tabletop, and when laying out the rail mortises, don’t omit the customary allowance above the highest of the mortise—about 3/4 in. for a 4-1/2-in. rail. Sq. up the highest of every leg and take all measurements from there. Construct the body and assemble dry, leaving the rails robust to be trimmed later. Sketch plans and elevations of the leg tops, taking into consideration that every one 4 pins have to be offset in the identical course, and that if the system is to be hid the pin size have to be a bit lower than half the leg thickness, an allowance being made for seasonal change within the width of the highest. Later within the building, when the body has been fitted to the housings, the escapements will probably be lengthened as nicely to accommodate this variation. For frames of abnormal dimension, about 30 in. throughout, divide the leg high into two pin lengths plus 1/8 in. at every finish, then lay out the pins utilizing a mortise gauge for the aspect and finish strains, and a small adjustable bevel, set to a beveled information block (about 78°), for the slopes.

Gauge the shoulder strains from the top. Make the 4 cuts outlining the pins, then noticed the shoulders. Trim with a pointy chisel, testing the work with the information block. End all work on the body besides sprucing.

Construct the highest and trim it sufficiently to heart the body. Scribe the define of the pins on the underside of the highest to mark their place when locked up, however observe that the define is of the crown of the pin reasonably than its root, which is definitely wished on this area.

Mark close to every define the course the body will journey when unlocking. Pencil in a benchmark on one leg and close by on the underside of the highest to register the placement, and take away the body.

Lay out the escapements by extending the scribed sidelines within the correct course a distance equal to the pin size, and join the brand new strains with an finish line. Discover the centerline alongside the size of this double field. Measure the width on the root of every dovetail pin and switch it to the structure of the housing, using the centerline. If the measurements differ from pin to pin, switch separately. Lower the escapements, first boring out with a Forstner or different short-pointed bit, then chopping sq.. There isn’t a benefit and a few hazard in going any greater than a trifle deeper than the peak of the pin. Check the body within the escapements to make certain that the shoulders of the legs lie flush with the underside of the highest. Stage as vital. Now take away the body and lay out the slopes of the housings, utilizing the adjustable bevel set to the information block. Bore out, then with a dovetail noticed tough out the slope, retaining somewhat robust of the road. Chop out the waste, once more retaining away from the road. Clamp the information block on the line and trim with a slender paring chisel, the ultimate cuts to be taken with the chisel proper in opposition to the block.

Lay the body within the escapements and see that the pins are prone to enter the housings. Then take away the body and chamfer the main corners of the pins. Change and push (or pull). Appreciable pressure could also be vital the primary few occasions; waxing the pins is useful. Nonetheless, a driving match means an excessive amount of interference. Often one joint will trigger the difficulty, or two that aren’t in parallel throughout the body. There will probably be sufficient flex within the body in order that tapping at every joint will inform which one is binding. In case you trim away an excessive amount of throughout changes, a chunk of veneer or cedar cigar wrapper (.009 in. thick) may be glued into the housing. When all is nicely, take away the body and stamp a benchmark into the highest of 1 pin and contained in the corresponding escapement. At this level take into account the possible shrinkage and growth of the tabletop, and lengthen the escapements accordingly. Spherical off all of the factors and corners of the pins and the entry corners of the housings, as in service the highest drops down over the pins, considerably by really feel. Then the close to pair of legs may be gripped and the highest pushed residence with chest or waist.

Pedestal body

Because the arms of a pedestal body don’t supply the suitable grain for slicing pins, separate pins have to be normal and joined to the arms. Make pin blanks of rectangular part, however with one sloping face within the size, then mortise in with a shim to drive the clean in opposition to a correspondingly undercut finish of the mortise. Noticed the slopes as soon as the clean is glued and trimmed. A clean might be fitted via the underside of the arm after which wedged beneath, however shrinkage within the depth of the arm would go away the pin standing proud and the joint free. One of the best orientation is for one set of arms to be perpendicular to the grain of the highest, the opposite parallel, with room left within the housings perpendicular to the grain for tabletop growth and contraction. In case you orient the arms at 45° to the grain of the highest, the system works however the housings received’t be as robust.

High quality Woodworking Beneficial Merchandise

Pfiel Chip Carving Knife

Nice to make use of as a marking knife for laying out joinery and straightforward to sharpen.

Veritas Commonplace Wheel Marking Gauge

A wheel-type gauge is the best to make use of, and this excellent Veritas mannequin is a steal at $38.

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

This heavy, double-beveled knife stays on observe in all instructions, and works simply nice with out including a deal with.

Join eletters as we speak and get the most recent strategies and how-to from High quality Woodworking, plus particular affords.